Special Bar Quality Steel TimkenSteel | High .

crosssection of special bar quality steel. ... Sizing Mill allows customers to request any size from 1" 5" ... design the optimal

WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

crosssection of special bar quality steel. ... Sizing Mill allows customers to request any size from 1" 5" ... design the optimal

Over 300 different Chamfering Tools stocked with angles from 15° to 75° per side, Harvey Tool Pointed Flat End Chamfer Cutters are available in 2,3 and 4 flutes!

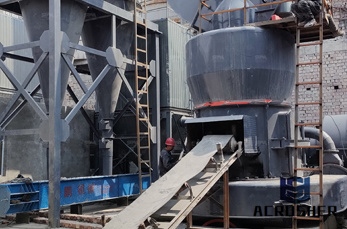

Wear Resistant Linings Excellent ... mill liners are satisfied. Before an optimal design and material can be recom ... mill power, ore type, feed top size, ...

reduce the particle size of feed ingredients. ... feed processors decide which mill ... MF2048 Hammermills and Roller Mills ...

Hexagonal Square Broaches Size: hex ... 1200 RPM with a feed rate of .016 times the size of the broach in inches for ... would be recommended for optimal

Rod mills – . The rod mills accept a feed size up to 2" and produce a typical product size of 5 to 10 . The rod mill performs best when making products having ...

Mill fresh feed particle size distribution was also determined using rod screens ... tumbling ball mill tests were performed. The optimal values of parameters of

Drilling Speeds and Feeds . ... speed and feed to reduce the amount of heat is ... * Table values are typical for cutters ranging from ½" to 1 1/2" in size. *

SAG mills are often flexible enough to accomplish the same size ... a rod mill, and some or all of ... preand postinstallation solutions to SAG mill power and feed ...

Mineral processing can involve four general types of unit operation: comminution – particle size ... which further belts ran at right angles to the feed ...

On Jan 1, 2007 Chen Xisong (and others) published: Override and Model Predictive Control of Particle Size and Feed Rate in Grinding Process

Find all the manufacturers of rotary drum mill and ... size for further grinding in a ball mill, ... horizontal feed unit. In order to grant an optimal shredding ...

Silica Sand Rod Mill Silica Sand Ball Grinding Mill, ... 5 ton an hr rod mill; copare operation of rod mill; optimal rod mill feed size; ball rod mills in india;

Includes 4 sieves to achieve desired feed size ... videos of the Ercolino Feed Grinder in ... both stainless steel and tinned copper filaments for optimal ...

... combined with optimal milling capacity makes this the ... TSlot Size: Draw Rod Size: Drill chuck / Arbor: Mill Head ... Mill Feed: Powerfeed XAxis: Powerfeed Z ...

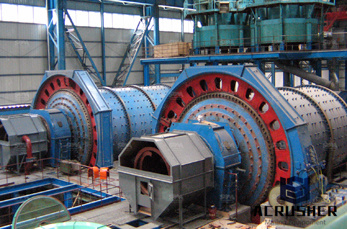

Ball grinding and rod grinding: Mill feed size: ... statistical modelling also allows us to predict the optimal ... E. ForssbergEffect of mill feed size on ...

Brochure Rod Mills EN The rod mill accepts feed ore as coarse as 1 1/2" top size although better performance is obtained by restricting ore feed size ...

Talk with the Experts at Paul O. Abbe about your process requirements and Ball Mill Loading, Wet Milling, Size Reduction and Mill Speed Critical Speed needs.

This CNC conversion plan allows you to retrofit your Siegbuilt X2 minimill to ... SPEED / FEED REFERENCE FOR TURNING, MILLING, AND DRILLING . ... its size along ...

AMIT 135: Lesson 6 Grinding Circuit. ... or an intermediate size ready for final grinding in a rod mill, ... AMIT 135: Lesson 8 Rod Mills

Feed Rate Calculator. See our other Electronics Calculators. When milling ... Disclaimer: Daycounter, Inc. doesn''t guarantee the accuracy of any of it''s content.

Mini Mill Power Feed. ... I used 3/8" dia. drill rod. ... but I decided to add a limit stop so that I could set the optimal point and then just engage the lever ...

Mill Linings, Mill Trommels and Trunnion Linings. ... finer feed size material. ... of Skega PolyMet® Mill Linings promotes optimal grinding performance while

The capacity of a screening machine is defined as the optimal feed rate to ... Discharge Rod mill EL PORVENIR ... Documents Similar To Application Screens.

WhatsApp)

WhatsApp)